Product categories

Tantalum wire

| Grades | RO5200, RO5400, RO5252, RO5255 |

| Standard | ASTM B365 |

| Size | Dia.: 0.1mm-5.0mm┬Ā ( tolerance: +/-0.05mm ) |

| Condition | Hot rolled, Cold drawn, Annealed |

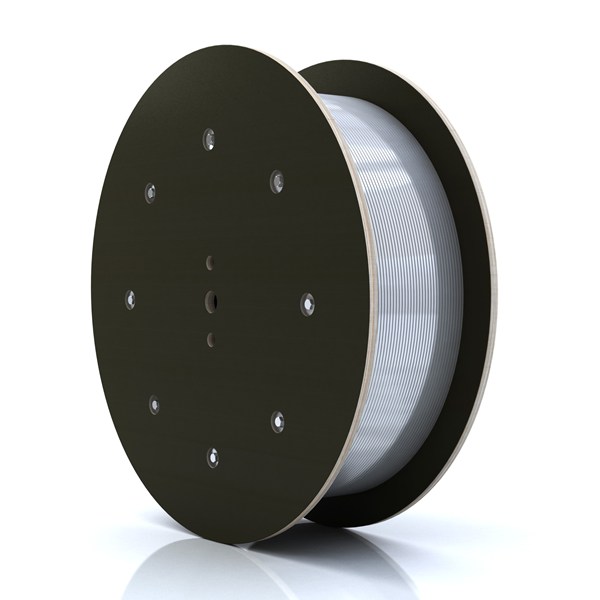

| Shape | Coils or CustomersŌĆÖ Requests |

| Surface | Black, Pickled, Polished ┬Ā( For Dia. >1mm ) |

| Packing | Standard seaworthy packages or as your requests |

As a large Tantalum Wire supplier, we can manufacture Tantalum Wire as customized with stable quality and reasonable price. We carry a fully-stocked facility for your convenience.

ZircoSCM

can supply tantalum wire with a premium surface finish, it has superior

performance in such applications.

Certification:

Tensile

Properties

Chemical

Composition

Customer

Specific Requirements

Heat Treatment’╝Ü

Tantalum

exhibits high reactivity towards interstitials elements like Hydrogen, Nitrogen

and Oxygen. Also it may react with Hydrocarbons. Its recrystallization

temperature varies between 900 ┬░C and 1450 ┬░C. Vacuum and dry inert gases are

most suitable as heat treatment atmospheres. The duration of the heat treatment

may depend on the equipment, the process and the experience with the material.

Lubricants should be completely removed prior to the heat treatment. If not,

they may react with the Tantalum and cause embrittlement of the material.

Remark: Special requirements

of tantalum wire will to be agreed on by the supplier and buyer of

negotiations.

Applications:

Tantalum

wire is widely used in electronic industry. It is mainly used as anodic lead

wire of tantalum electrolytic capacitor. Tantalum wire was the first material

used for filaments in light bulbs. Tantalum wire is also used in the electronics industry

in the manufacture of rectifiers and capacitors. Other applications include

medical devices, chemical processing, and lighting applications. Whether in the

cold and hot conditions, hydrochloric acid, concentrated nitric acid or in

"aqua regia", tantalum wire has no chemical reaction. In medicine,

tantalum is used to make flakes or sewing thread to mend the destructive

tissue.